Al-Jazari for Engineering Consultation and Technical Development

Welcome to Al-Jazari Engineering Consultation and Technical Development Company, a leading institution in the field of mechanical and technical engineering. Through many years of experience and dedication in the field of engineering, we strive to provide innovative and cutting-edge solutions that meet our customers’ needs with the highest levels of quality and efficiency.

Al Jazari Company relies on a team of distinguished experts and engineers who have extensive experience in multiple fields of mechanical engineering, including design, analysis, manufacturing and maintenance. We fully understand the complexities of engineering projects and strive to provide comprehensive solutions that meet and exceed our clients’ expectations.

Our mission is to provide distinguished consulting services that help our clients achieve their goals and continuously improve their performance. Whether you are looking to design and develop a new product, improve existing manufacturing processes, or implement effective maintenance procedures, we are here to help.

In the end, our customers’ satisfaction is the ultimate goal that we strive to achieve in every project we undertake. If you are looking for a reliable and dedicated partner in the field of mechanical engineering, you are definitely in the right place with Al Jazari Company.

We look forward to the opportunity to cooperate with you and provide the distinguished engineering services you deserve.

One of the most important services in the company

Supervising the implementation of projects

1. **Planning and Analysis**: Implementation begins with the careful planning and analysis phase, where the project objectives are defined and potential requirements and risks are identified. Engineering experience and expertise are used to analyze the current situation and determine the steps necessary to achieve goals as efficiently as possible.

2. **Design and Development**: After defining requirements, the engineering team begins creating innovative designs that meet the client’s needs. The latest technologies and tools are used to develop effective and sustainable technical solutions.

3. **Implementation and coordination**: The project is implemented carefully and precisely according to pre-determined plans. Al Jazari’s team oversees every step of implementation to ensure compliance with specifications and schedule.

4. **Quality control and testing**: The quality of work is monitored periodically during the implementation process. Necessary tests are performed to verify the performance of products and processes and ensure their quality and reliability.

5. **Delivery and Support**: Once the project is completed and set goals are met, the product or service is delivered to the customer. However, post-delivery support continues to ensure complete customer satisfaction and provide technical support and maintenance when needed.

These processes are conducted under close supervision by Al Jazari’s team to ensure that projects are implemented with high efficiency and maximum customer satisfaction is achieved.

CMMS computerized maintenance management system

It is a program that helps maintenance teams schedule, organize, track and optimize maintenance tasks in one place. This includes the ability to

Plan, manage, track, measure and optimize everything from work orders to inventory, reporting and performance indicators. Briefly,

CMMS software is what maintenance teams in asset- and equipment-intensive industrial organizations and companies use to organize information,

Ensure the completion of the work, and measure the impact of this work on the company’s performance.

CMMS software provides planning, management and measurement of your maintenance process, including reactive maintenance and preventive maintenance

and predictive maintenance. A CMMS centralizes facility maintenance information, allowing you to automate any asset maintenance task.

CMMS software also eliminates paperwork and time-consuming activities, thus enabling employees to carry out tasks

more important and enabling them to be more productive and proactive

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0001](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0001.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0002](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0002.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0003](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0003.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0004](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0004.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0005](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0005.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0006](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0006.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0007](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0007.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0008](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0008.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0009](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0009.jpg)

![نظام إدارة الصيانة المحوسب Manwinwin[2]_page-0010](https://aljazari.ly/wp-content/uploads/2024/05/نظام-إدارة-الصيانة-المحوسب-Manwinwin2_page-0010.jpg)

For more details, download the file

Providing engineering consultation

1. **Needs Assessment**: The work begins with understanding the customer’s needs and the problem he faces. Available information is surveyed and the current situation is analyzed to accurately determine needs.

2. **Data and information analysis**: Relevant data and information are collected and analyzed to provide an accurate assessment of the problem and identify available options for a solution.

3. **Developing technical solutions**: The engineering consulting team develops a set of possible technical solutions to the identified problem, taking into account technical, economic and environmental considerations.

4. **Providing recommendations**: Based on the analysis and evaluation, appropriate engineering recommendations are provided to the client, including the proposed steps to implement the recommended solutions.

5. **Follow-up and evaluation**: The implementation of the proposed solutions is monitored and their performance is evaluated regularly to ensure the achievement of the desired results and continuous improvement.

These processes are carried out in close cooperation between the engineering consulting team and the client to ensure that the objectives are achieved effectively and sustainably.

Training and education services

Al-Jazari’s training is characterized by an ideal balance between practical and theoretical aspects, as it aims to provide participants with the knowledge and skills necessary to succeed in the field of mechanical engineering. Here is an explanation of the training provided by Al Jazari Company:

1. **Theoretical training**:

This type of training includes educational sessions and lectures covering basic engineering concepts and theories related to the field of mechanical engineering.

– Various educational resources such as books, articles and online learning materials are provided to enhance participants’ understanding of complex topics.

2. **Practical training**:

– It focuses on applying theoretical concepts in a practical environment through practical projects and practical experiences.

– Practical training provides participants with an opportunity to develop their technical and practical skills through interaction with modern equipment, tools and techniques.

3. **Workshops and simulations**:

Al-Jazari offers workshops and simulations to simulate practical environments and realistic situations that engineers can face in their field.

These workshops provide opportunities for participants to interact, exchange experiences, and solve problems practically.

4. **Personal guidance and follow-up**:

Al-Jazari provides ongoing support to participants through individual guidance and follow-up sessions to ensure their full understanding of the materials and their progress in training.

Through these integrated methods, Al-Jazari seeks to provide a comprehensive training experience that combines theory and practice to qualify participants and enable them to make the most of the training.

Some of our work

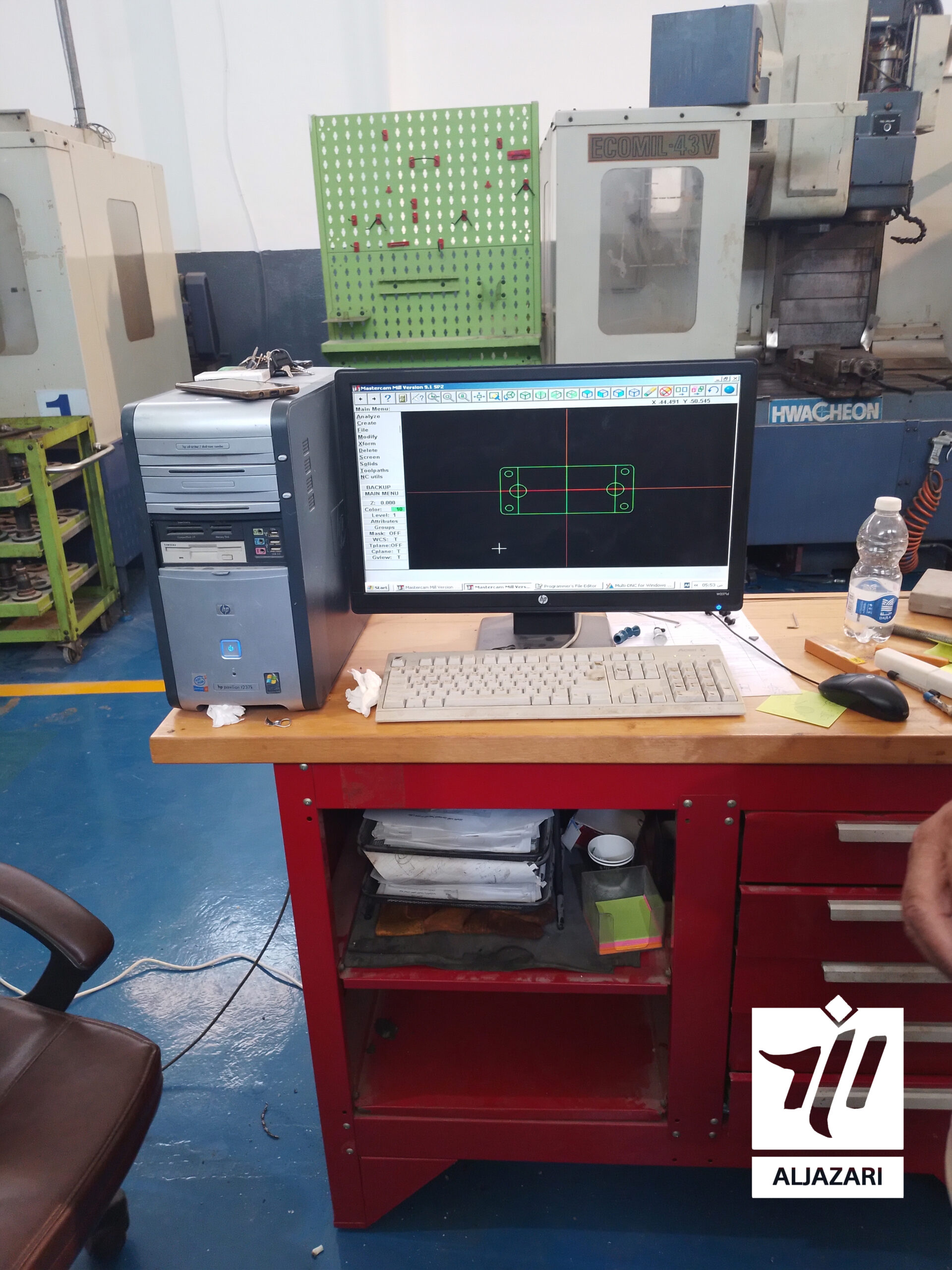

Providing modern design and technical software of an engineering nature

In the world of engineering mechanics, providing modern design software and technology is crucial to enabling engineers to implement their projects efficiently and accurately. Here are some examples of modern software and technologies in this field:

1. **CAD/CAM/CAE software**: It includes CAD/CAM software and is essential in the process of designing and manufacturing products. This software includes tools for drawing three-dimensional (3D) models, analyzing parts and assemblies, and programming numerical control (CNC) machines.

2. **Engineering Analysis (FEA) Software**: Analysis software allows accurate analysis of the behavior of materials and parts under the influence of external forces, which helps improve the design and reduce potential failure.

3. **Modeling and simulation software**: This software allows creating virtual models representing a specific mechanical system, and testing its behavior under different conditions such as loading, vibration, and thermal effects.

4. **Data Management and Collaboration Software**: This software is used to manage data and documents and facilitate collaboration between different team members on mechanical engineering projects.

5. **Additive manufacturing technologies (3D printing, etc.)**: Additive manufacturing technologies offer innovative methods for producing parts of high complexity and complex structures quickly and at low cost.

Preparing the needs of engineering designs for industrial, craft and commercial buildings.

Preparing needs engineering designs for industrial, craft and commercial buildings requires a comprehensive process that takes into account a variety of factors and requirements. Here’s an explanation of how to set up these requirements:

1. **Analysis of requirements and needs**: The work begins with carefully analyzing the building’s needs. This includes understanding the nature of the commercial or industrial work taking place in the building, the expected operational processes, and requirements for safety, health and the environment.

2. **Site and environment study**: The potential location of the building is evaluated and surrounding factors such as terrain, soil, and environmental trends are studied. Local laws and legislation applicable in the region are also studied.

3. **Building and structural design**: Engineering designs for the building and structural structure are developed based on the information specified in the previous steps. This includes determining the dimensions, structural materials, and structural design of the building.

4. **Systems and Equipment Design**: This includes the design of electrical, plumbing, air conditioning, lighting, fire, security, and other engineering systems necessary for the effective operation of the building.

5. **Decorative planning and finishes**: Interior design, decorations and finishes are planned according to the needs of users and business requirements, taking into account functional and aesthetic elements.

And many services provided by Al-Jazari Company

Occupational security and safety in industrial enterprises refers to a set of policies and procedures aimed at protecting the health and safety of workers and employees in the workplace. This includes providing appropriate training to workers, providing the necessary protective equipment, implementing accident prevention measures and protecting against potential hazards such as fires, explosions, and exposure to harmful chemicals. This work aims to create a safe and healthy work environment for everyone, reduce work accidents and injuries, reduce costs and losses resulting from them, and enhance productivity and sustainability in industrial institutions.

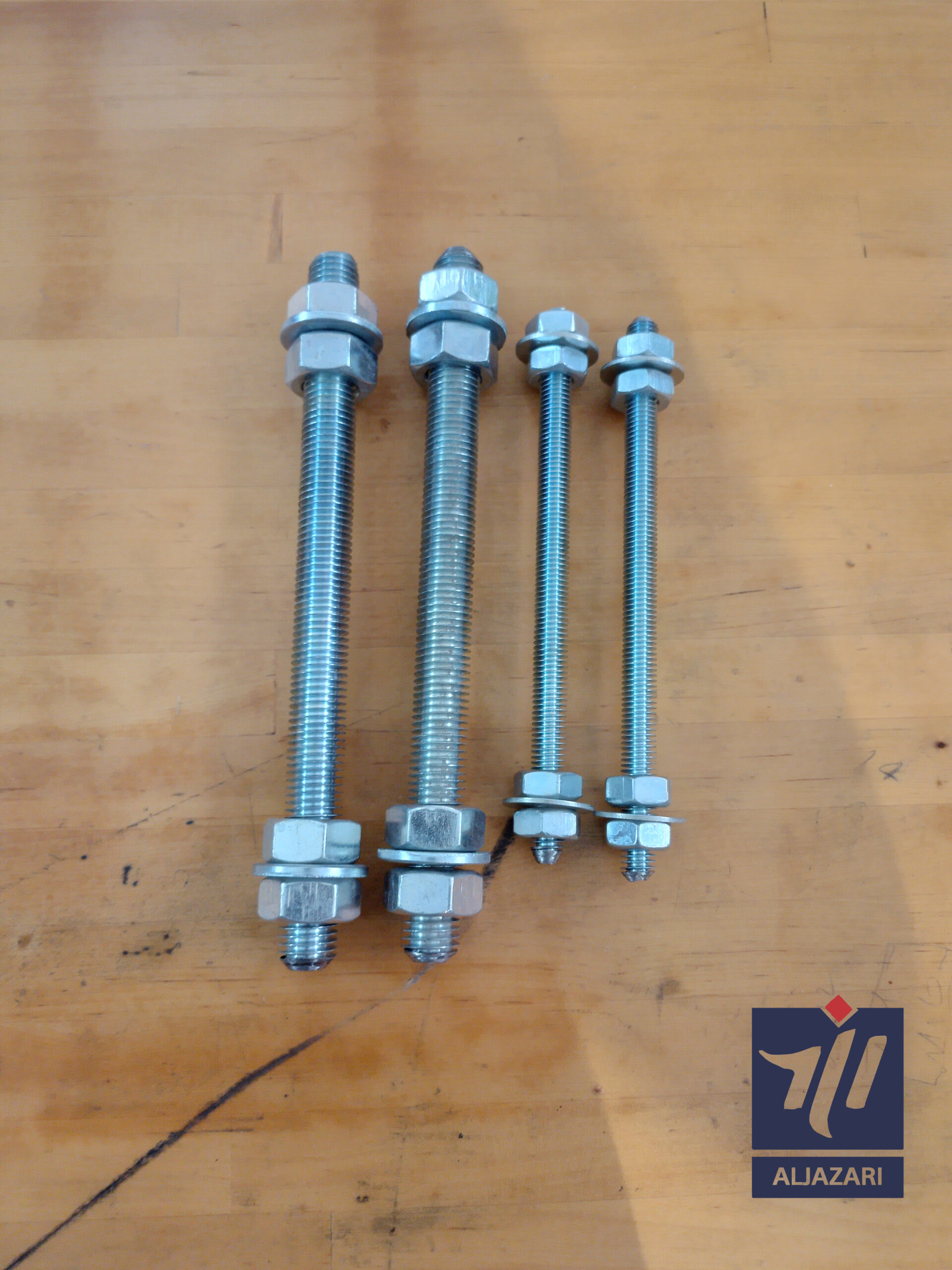

Manufacturing and supplying spare parts is an essential part of managing the maintenance of equipment and production units. This work includes manufacturing replacement parts for damaged or worn-out equipment and providing them to customers in accordance with the original manufacturer’s specifications. The process includes:

1. **Identifying requirements**: Identifying the parts that need to be manufactured based on orders received from customers or based on regular maintenance needs.

2. **Replacement Parts Design**: Engineering designs for replacement parts are created based on the technical specifications and functional requirements of the equipment.

3. **Manufacturing Process**: Parts are manufactured using appropriate techniques and equipment, whether traditional manufacturing or using additive manufacturing techniques such as 3D printing.

4. **Quality Check**: The manufactured parts are inspected to ensure that they meet the required specifications and standards in terms of quality and accuracy.

5. **Distribution and Delivery**: Replacement parts are distributed to customers or to maintenance departments within the facility so that they are available in a timely manner to meet needs.

In establishing regular maintenance programs for production units, specific guidelines are provided for regular maintenance of equipment based on a specific schedule. These programs include activities such as periodic inspections, lubrication, performance checks, repair of minor faults, and regular replacement of consumable parts. These programs aim to maintain equipment efficiency, avoid unplanned downtime, and reduce long-term maintenance and repair costs.

Maintenance of mechanical and electronic equipment includes a set of procedures aimed at maintaining the equipment’s performance in the best possible condition and avoiding malfunctions and damage. This maintenance includes periodic cleaning and inspection, lubrication and adjustment of mechanical parts, and testing and debugging of electronic circuits, with the aim of enhancing efficiency and reliability and extending the service life of the equipment.

Mechanical vibration analysis is the process of studying and evaluating oscillatory motion in mechanical systems such as engines or machines. This analysis aims to understand the behavior of the system and estimate the effects resulting from vibrations such as wear or premature damage

A brief overview of industrial electricity services:

1. **Electrical installations**: This includes installing and maintaining electrical wires and cables, and connecting them to industrial devices and equipment.

2. **Installing electrical appliances and equipment**: This includes installing and maintaining electrical motors, control devices, and electrical conversion units.

3. **Energy Distribution**: Planning and implementing electricity distribution systems within industrial facilities to ensure efficient and safe distribution of energy.

4. **Control and Automation**: Installing and programming automatic control systems and automating industrial processes to ensure efficient operations and improve productivity.

5. **Maintenance and Repair**: Providing periodic maintenance and repair services for electrical systems to maintain their optimal performance and avoid unplanned downtime.

6. **Energy analysis and evaluation**: Providing consultations to improve energy efficiency and providing solutions to reduce costs and excess electricity consumption.

These are some of the main services in the field of industrial electricity, and the needs and services required vary according to the type and size of the industry and customer requirements.

Design and operation of mechanical engineering systems and networks refers to the process of developing and designing systems and networks that are used in a variety of industrial and commercial applications. These engineered mechanical systems and networks include pressure piping, refrigeration and air conditioning systems, plumbing systems, firefighting systems, and other mechanical equipment.

The first stage in this process is design, which includes steps such as:

1. **Determine requirements**: Understand the client’s needs and project requirements, including required capacity, flow, pressure, environmental conditions, and any standards or regulations that may be required.

2. **Engineering Design**: This includes steps such as selecting appropriate materials, size and capacity calculations, designing piping and fittings, and planning for safe and efficient operation.

3. **Schematic drawing**: Engineering drawings and diagrams that accurately describe systems and networks, including piping routes and equipment arrangement.

After design, comes the system operation stage, and these steps include:

1. **Installation and assembly**: Systems and networks are installed and assembled according to the specified engineering design.

2. **Testing and initial commissioning**: Systems and networks are tested to ensure that they operate properly according to specified specifications, and the necessary modifications are made if necessary.

3. **Maintenance and Service**: Regular maintenance and service are provided to ensure the continued operation of systems and networks with high efficiency and without problems.

These are some of the basic steps in the process of designing and operating engineering mechanical systems and networks, and this process requires good coordination between engineering and technical teams to ensure successful and effective implementation of projects.

A brief explanation of the design, detection and analysis work:

1. **Design**:

-At this stage, the requirements and specifications for the project are determined based on the client’s needs and the purpose of the project.

– Creates visualizations, plans, and engineering drawings that illustrate the technical details of the project, including materials used, dimensions, and other engineering details.

– Available data and requirements are analyzed to ensure the best possible design that meets the client’s needs and complies with technical standards and industrial laws is achieved.

2. **Inspection**:

Inspection refers to the inspection and evaluation of materials or structures made to ensure their quality and safety.

– A variety of tools and techniques are used to examine materials, such as non-destructive testing such as X-ray imaging and ultrasound testing.

– Possible defects or anomalies in design or manufacturing are also detected to make necessary corrections.

3. **Analysis**:

Analysis involves using tools and techniques to understand and evaluate available data and transform it into useful information.

– Available data is analyzed in order to make the right decisions about the project, whether it is cost estimates, technical evaluation, or performance forecasting.

– Analysis is used to improve processes and technologies and develop new solutions to complex challenges faced by engineering projects.

Design, detection and analysis work plays a critical role in engineering processes, contributing to ensuring the quality, safety and effectiveness of the final product.